Scraps to Scrolls: Can Food Scraps be Utilized Into an Alternative to Traditional Wood Pulp Paper?

Grade 8

Presentation

Hypothesis

Objective

The project aims to explore the use of vegetable waste as a sustainable alternative to wood pulp paper, to identify which vegetable pulp produces the best paper in comparison to A4 paper. We will be comparing the durability, functionality, and aesthetics of paper made from six different vegetables. It also evaluates water holding capacities and weight to determine the most suitable vegetable pulp for this purpose. Ultimately, the project seeks to determine whether vegetable waste can be used as a sustainable and eco-friendly alternative to traditional paper production, and to identify the most suitable vegetable pulp for this purpose.

Question

Overarching Question: Is it possible to reuse vegetable waste and reduce our ecological impact on the environment?

Main Problem: Can vegetable scrap pulp produce a sustainable alternative to wood pulp paper, if so, which vegetable pulp will produce the best paper in comparison to A4 paper?

Hypothesis

If we take the pulp from six different vegetables, (carrots, peas, cabbage, potato, cauliflower, and radish) and make it into paper, the peas will provide the most durable and functional paper in terms of writing tests, thickness, aesthetics, weight, and water holding capacities, because they have the highest cellulose concentration and the fibre content is the most similar to wood pulp.

Research

Abstract

In an era where sustainability and environmental consciousness are paramount, understanding the enduring resilience of paper against decay is of critical importance. Despite being primarily composed of organic materials, paper exhibits remarkable resistance to decay in everyday use. This durability stems from the careful production procedures and intrinsic qualities of its main constituent, cellulose. The composition of paper is treated to remove lignin, which increases the material's resistance to oxidation and degradation. Wood pulp makes up the majority of the composition. Dense fibre structures developed during production act as physical barriers that prevent enzymatic breakdown and microbial penetration—two processes that are essential to decay. Paper is further strengthened by industrial processes by chemical treatments that prevent microbiological growth. Because of the synergistic effects of composition and manufacturing techniques, paper has withstood the test of time in terms of preservation and utility.

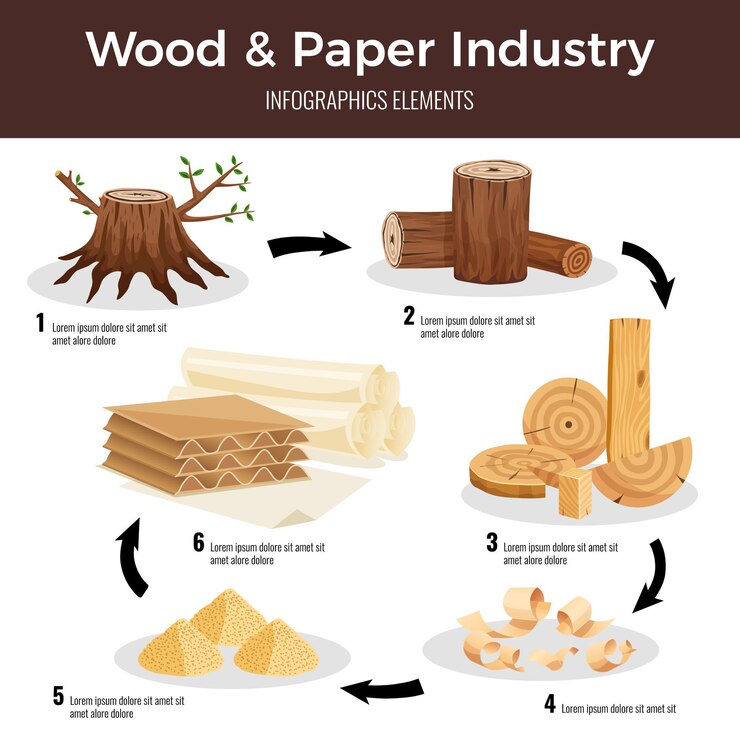

Why is Paper Made from Wood?

Wood is abundant, easily accessible, and versatile, making it multipurpose and a primary source for paper production. It also has a high fibrous content, which serves as the main component and helps with binding in papermaking, as well as being cost-effective for large-scale manufacturing, which is another big contributor. One of the most important and first steps in paper making is selecting wood, which is usually categorized into two types: hardwood and softwood. Softwood fibers are long and sturdy, making them ideal for manufacturing strong paper grades like cardboard boxes and milk cartons. In contrast, hardwood fibers are short and thin, providing a smooth printing surface and high opacity. Usually, paper manufacturers combine hardwood and softwood pulps to create the optimal paper that meets the demands of consumers. The Chinese invented the first true paper made from mulberry bark, hemp, and cloth rags, and this led to early western paper, which was made from discarded rags. However, when European developments in the mid 1800s discovered tree fibers, wood pulp became the primary source due to its abundance. Fast forward to modern day, paper production primarily uses wood pulp, while cotton and linen fibers are primarily used for specialty papers.

What is the Papermaking Process?

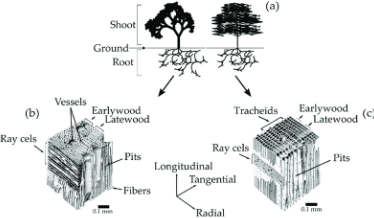

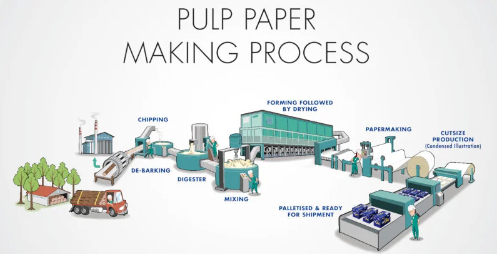

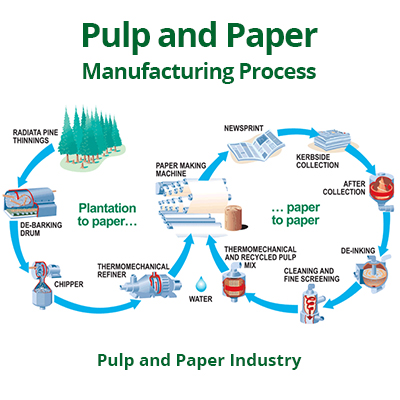

Papermaking starts with choosing wood, and is usually categorized into two types: hardwood and softwood. Fibers from softwoods are long and strong, and therefore the strongest paper grades are generally manufactured from chemical pulp made of softwood. Typical important end uses for softwood include cardboard boxes and milk cartons, which require high strength to function correctly. Softwood (b) is composed of up to 90% long, tapering cells called tracheids, which serve dual functions for support and water transportation. Hardwood (c) fibers, being short and thin, contribute to better paper formation compared to softwood fibers, providing paper with a smooth printing surface and high opacity. Hardwood has somewhat less lignin compared to softwood, making it easier to bleach the hardwood pulp to achieve high brightness. These qualities make hardwood very suitable for use in printing papers. Generally, paper consists of a blend of hardwood and softwood pulps to meet the combination of strength and printing surface demands of the customer. Softwood fibers are long and strong, making them ideal for manufacturing strong paper grades like cardboard boxes and milk cartons. Softwood contains up to 90% long tracheids, for dual functions, such as support and water transportation. Hardwood fibers are short and thin, providing a smooth printing surface and high opacity. Hardwood has less lignin, making it easier to bleach for high brightness. Paper typically combines hardwood and softwood pulps to meet customer demands for strength and surface. Before wood pulp is produced, several steps must be taken. After trees are cut and transported to the mill, the bark is removed from the trees. Mechanical grinding involves grindstones tearing wood fibers apart in water, or the trees are chopped into small pieces first and then ground down to fibers. Chemical methods, more widely used and energy-efficient, involve cooking wood chips in large tanks with various chemicals, known as the cooking liquor. This process helps break down wood chips into a mushy mass of fibers. Pulp, chemicals, and water create a "slush" that moves through papermaking machines. The slush is pressed, dried, and smoothed, ultimately producing rolls of paper. Throughout this entire process, quality tests ensure the final product meets standards.

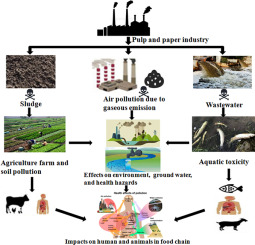

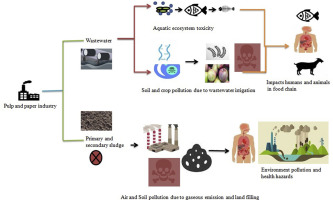

What are Problems With Wood in Papermaking?

Although papermaking has been using wood as its primary raw material for centuries, with global warming and environmental issues becoming more prominent, especially within the past few years, a couple problems have started to arise. Firstly, almost every phase of paper manufacturing involves water. To make just a single A4 sheet, you need between two and 13 liters of water. After the pulping and bleaching is over, paper mills end up with water containing a cocktail of organic compounds, alkalis, and bleach, which must be treated so that it can be disposed of safely. This can be a huge challenge, which usually means paper mills simply discharge the effluent straight into the local water supply, where it’s acutely toxic to fish. Another sustainability challenge facing the paper industry is the amount of energy required, which contributes 2% of the world’s total carbon footprint. However, using a softer material such as vegetable matter could use less energy, as the material is softer and easier to break down compared to wood. Lastly, and perhaps the most important element, is the environment. The global paper industry is fed by more than 100 billions trees each year, which a space comparable to the size of Egypt. Additionally, the global paper industry consumes over 100 billion trees annually. While much paper is sourced from sustainably managed forests, some is made from trees in ecologically important spaces, contributing to loss of biodiversity and destruction of ecosystems. This is the contributing factor that our food waste paper would be most helpful to, as it would both prevent deforestation while battling the problem of excessive food waste.

Professor S. Lacorte in the Department of Environmental Chemistry, at the University of Barcelona believes, “Excessive food waste should be dealt with properly, while food waste compost is a fantastic idea, but alternatives should always be an option, and environmental friendly practices are most in need of, now more than ever. Food waste releases greenhouse gasses that worsen climate change and wastes the resources needed to cultivate, produce, and deliver the food to customers. Reducing food waste and deforestation is a two in one solution contributing to a better life for not only us, but also everything that surrounds us.” Collaboration with local grocery stores could create a collection system for waste that would otherwise be disposed of. When we did contact certain grocery stores to gather more information, they stated most of their scraps go to waste, as supported by our background research which further aids in the functionality and practicality of our project.

What are the Most Important Components to Make Paper?

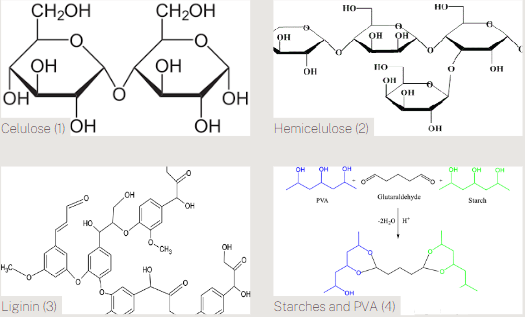

Wood pulp paper is primarily composed of cellulose, hemicellulose, and lignin. Cellulose forms a strong structural material through its glucose units. Hemicellulose is branched molecular chains of glucose and other monosaccharides. Despite shorter molecular chains than cellulose, hemicellulose's significance lies in promoting fiber-to-fiber bonding by aiding in water absorption during processing. Lignin acts as an adhesive, holding fibers together in the wood structure. Chemical pulping processes aim to dissolve and remove lignin, which imparts a brown tint to unbleached pulp and hinders fiber-to-fiber bond formation. In addition, papermaking involves the incorporation of starches and PVA, crucial agents facilitating the binding of the paper slurry, ultimately transforming it into the sheets we use. Starch is used as a flocculant and retention aid and as a bonding agent, some examples include corn, potato, waxy maize, wheat, and tapioca. Polyvinyl alcohol (PVA) is a water soluble polymer having high film forming ability that makes it a good surface sizing agent. Surface sizing agents are commonly used to provide water-resistance and prevent paper from blurring with water or ink. These agents are applied to a wide variety of paper.

Mould and deckle is a common part used in homemade paper making. A deckle is a removable wooden frame or "fence" used in manual papermaking. The mould is the bottom part that has a frame, usually wood, with some kind of screening stretched over it. The deckle is the top part and is a frame of the same size as the mould. The deckle fits on top of the mould and it helps to keep the pulp contained on the screen and creates the edges of the paper.

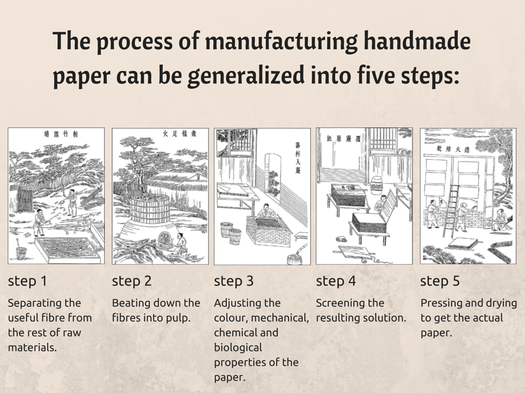

Can You Make Paper at Home?

In the realm of homemade paper production, two distinct methods are employed for pulp preparation. The first method involves adding raw pulp to a screen, pressing it with a microfiber cloth to remove excess water, and carefully transferring it to a moistened surface for further drying. On the other hand, the second method employs a boiled pulp preparation to create a stronger and more uniform sheet. In this method, the pulp is boiled with water and baking soda, strained, rinsed to remove brown liquid, and then mixed with a saline solution before draining excess liquid. For this project, we decided to use the first method since we focused on testing the raw pulp, as well as eliminating more sources of error that could be possibilities. This is also so we can try to avoid textural difficulties that we may face with cooked vegetables, helping aid in our controlled variables. we also found that To achieve flatter sheets, it's suggested to use more skin fibers, and adding other fibers like stems or leaves can strengthen the paper. however, just like the boiling method in the paper formation process, we just decided to use the whole vegtable to avoid sources of error, not adding or removing any additional stems/skins.

A faster, more mechanised method was developed due to the traditional process's length and the increasing demand for paper. Many started using a mesh net in a wooden frame for more practical usages, saving time and materials. Nonetheless, there are still some elements of tradition present in this modern process. In this process, the percentage of paper that is not made of wood pulp—the low-cost substitute used in mass production—is frequently used to gauge the process's quality.

For this project, we will utilize various materials to experiment with vegetable waste paper production. These include a knife, table, and chopping board for vegetable preparation. Each vegetable, namely Daikon Radish, Danvers Carrot, Yukon Gold Potatoes, White Cauliflower Head, Napa Cabbage, and Cultivated Peas, will be processed into 200g of pulp. Typical office paper has 80 g/m2 (0.26 oz/sq ft), therefore, a typical A4 sheet (1⁄16 of a square metre) weighs 5 g (0.18 oz). Using these measurements, we can estimate that we would need about 5g multiplied by 10, or 50 grams of vegetable waste. However, because the cellulose fibres in vegetables are less prominent than wood, it would be safer to create a thicker paper especially when considering the higher water content in produce waste. Because of this, at least doubling the amount of raw pulp should produce the optimal amount of stability as well as flexibility.

Why Doesn't Paper Rot?

Paper does not readily rot due to several key factors in its composition and production process. Firstly, paper is primarily made from cellulose fibres derived from wood pulp, which are tightly bound together during manufacturing. This dense structure creates a physical barrier that impedes microbial penetration and enzymatic breakdown, slowing down the decay process. Paper's resistance to rotting stems from its composition and manufacturing processes. Cellulose, the primary component of paper derived from wood fibers, forms a densely packed network during production, which hinders all chances of moisture and microrobes, essential parts in decomposition. Additionally, many types of paper, especially higher quality varieties like acid-free paper, undergo treatments to remove lignin, a compound that is more susceptible to oxidation and degradation. This removal enhances the paper's resistance to ageing and decay. Moreover, industrial processes often involve the use of chemicals and techniques that further inhibit microbial growth and decomposition. Ensure a high cellulose content and properly pressed papers removing all air will leave the papers to stay perserved. Overall, the combination of dense fiber structure, lignin removal, and chemical treatments make paper a durable material that resists rotting over time.

Which Vegetables Work Best for Paper Making?

Peas, such as cultivated peas (Pisum sativum), exhibit high levels of cellulose due to their peels containing a waxy material, contributing to approximately 5.7 grams of fiber per kilogram. Despite potential waste from unutilized pea pods during harvesting and processing, they remain cost-effective at $2.00 per kilogram. While pea pods themselves aren't typically large, peas are often grown in substantial quantities, providing ample raw material. Commonly used in culinary dishes, peas are readily available in certain regions.

Green cabbage, particularly common or round cabbage varieties, is known for its cost-effectiveness, priced at $1.50 per kilogram. Although not particularly high in cellulose, cabbage still contains approximately 2.5 grams of fiber per kilogram. Waste often stems from discarded outer leaves and cores, although some parts may find use in other food products or composting. Growing to substantial sizes, common cabbage varieties offer a decent amount of plant material. Widely used in various cuisines, green cabbage is a staple in many dishes and is commonly available in most markets.

Regular white cauliflower, with its moderate cellulose content of approximately 2 grams of fiber per kilogram, is commonly available and cost-effective at $2.50 per kilogram. While cauliflower heads aren't typically large, choosing regular-sized heads can still provide a decent amount of plant material. Widely used in various cuisines, white cauliflower is readily available in most markets.

Yukon Gold potatoes, priced at $2.50 per kilogram, are known for their larger size compared to some other potato varieties, contributing approximately 2.2 grams of fiber per kilogram. With their high cellulose content due to the large size and waxy appearance of fibers, potatoes are commonly used in the food industry and households, making them readily available. Waste from potatoes may include peels and parts that are not consumed, influenced by cooking and preparation methods.

Danvers carrots, priced at $2.75 per kilogram, are commonly found in grocery stores and are known for their moderate cellulose content of approximately 2.8 grams of fiber per kilogram. These carrots, particularly Imperator or Danvers varieties, offer a reasonable amount of raw material for experiments. Waste often stems from discarded carrot tops and trimmed ends, although carrot tops can be repurposed in recipes or composted.

Daikon radishes, known for their large size and versatility, can have a decent amount of cellulose, contributing approximately 1.6 grams of fiber per kilogram. Depending on location and availability, daikon radishes can be relatively cost-effective at $3.00 per kilogram. Waste may include leaves, stems, and parts not consumed, which can be composted or used in other applications. Commonly used in various cuisines, daikon radishes are readily available in some markets.

Which Type of Paper is the Most Widely Used and Why?

The A4 paper size, measuring 210 × 297 millimeters or 8.27 × 11.69 inches, stands as the most extensively utilized type of paper worldwide. It finds widespread application across Europe, Asia, and increasingly in the Americas, serving various purposes such as document printing, report compilation, letter writing, and general office use. Its dominance can be attributed to several factors. Firstly, A4 paper benefits from standardization, adhering to the ISO 216 standard, which has been widely adopted by numerous countries. This standardized dimension facilitates international communication and commerce. Additionally, the compatibility of A4 paper with a range of office equipment, including printers, copiers, and scanners, ensures seamless document handling across different devices and systems. Moreover, its cost-effectiveness stems from large-scale production, resulting in competitive pricing advantageous for businesses and individuals alike. . It is the most common paper size for business documents, school reports, flyers, menus, letterheads and door signs. As the name of its North American equivalent suggests, it's also the most common size for letters. The versatility of A4 paper allows for its adaptation to various uses, offering ample space for content while remaining convenient for handling and storage. Lastly, the widespread availability of A4 paper in most office supply stores ensures easy accessibility for procurement and replenishment. Standardization, compatibility, cost-effectiveness, versatility, and availability solidifies A4 paper's position as the best choice for printing and office applications globally.

Benefits of Using Vegetable Paper in Comparision to Wood Pulp Paper?

Using vegetable paper, also known as plant-based paper, offers several benefits compared to traditional wood pulp paper. Firstly, vegetable paper is more environmentally sustainable as it is made from renewable plant sources such as bamboo, hemp, sugarcane, or recycled agricultural residues. This reduces the need for harvesting trees, thereby lowering deforestation rates and promoting sustainable land use practices. Additionally, vegetable paper production typically involves fewer chemicals compared to wood pulp paper manufacturing, resulting in lower emissions of harmful pollutants and a reduced environmental footprint. Moreover, vegetable paper production requires less energy, often utilizing less intensive mechanical methods or renewable energy sources. Despite its eco-friendly production process, vegetable paper can offer comparable or even superior quality to wood pulp paper in terms of strength, durability, and printability. Its versatility allows for use in various applications across industries, including printing paper, packaging materials, and specialty papers. Furthermore, vegetable paper is biodegradable and compostable, making it a more environmentally friendly option at the end of its life cycle. Many vegetable papers are also recyclable, reducing waste and conserving natural resources. Lastly, vegetable paper is generally considered safer for use, particularly in applications such as food packaging, as it does not contain harmful chemicals used in the pulping process of some wood pulp papers. Overall, vegetable paper provides numerous environmental, economic, and health benefits, making it an increasingly popular choice for environmentally conscious consumers and businesses seeking sustainable paper solutions.

Variables

Manipulated: Type of vegetable scraps used

Controlled: Time of experiment, location, amount of water used, weight of food scraps used, condition of food

scraps, processing method, uniformity in pulping, mixing, pressing, and drying, time between each step, time to

dry, conditions to dry in, consistency/thickness of the pulp, the pressure put into the pressing of the paper,

temperature, humidity, time of day, same tools used, cleanliness of the tools used, same timeframe, amount of

material used, same type of water, same materials, etc

Responding: The paper made by each fruit/vegetable and its evaluation the quality of the produced paper, such

as tensile strength, thickness, absorbency, and durability

Procedure

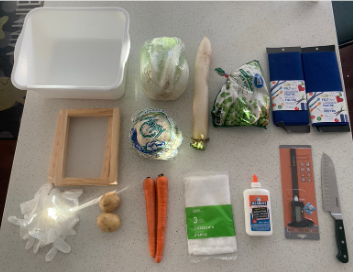

Materials

- Knife

- Table

- 6 Bowls

- 6 Chopping Boards

- 42 grams Unprocessed corn starch (each vegetable)

- 200g Daikon Radish pulp

- 200g Danvers Carrot

- 200g Yukon Gold Potatoes

- 200g White Cauliflower head

- 200g Napa Cabbage

- 200g Cultivated Peas

- Vat

- Blender

- Computer (Logbook)

- 25 ml Visio pva (each vegetable)

- Felt

- Mould and Deckle

- Sponge

- Press Bar

- Towel

- Drying Surface

- Measuring Flask

- PPE

- Dropper

- Weights

- Micrometer

- Water

- Flashlight

- Sharpie Black Marker

- Cheese Cloth

- Paper Towel

Procedure

1. Gather materials

2. Wash vegetables

3. Cut all vegetables into small pieces on your chopping board

4. Individually, by vegetable, put the pieces into the blender for 30 secs

5. Add 2000 ml of water to the tub

6. Add processed vegetables to the tub

7. Mix until pulpy consistency

8. Add 42 g starch

9. Add 25 ml Elmer’s glue

10. Soak for 10 mins

11. Hold mould with the screen side up, place deckle on top

12. Dip at a 45 degree angle

13. Dip the frame into the pulp mixture, ensuring the pulp evenly covers the entire screen

14. Scoop up while keeping the mould horizontal

15. Lift the mould and deckle up out of the pulp

16. Let water drain onto the vat from 8-10 seconds

17. Gently tap the frame on the edge of the basin to help the draining process

18. Carefully lift the mould from the deckle

19. Gently place the mould onto the felt, lay down the mould with the paper facing the felt

20. Place a piece of nylon or cheesecloth over the pulp layer

21. Use a sponge to press out excess water

22. Place another felt piece on the paper

23. Put press bar on top of the felt, sit for 1 minute.

24. Transfer to paper towel

25. Make nine sheets of paper for each vegetable

26. Let it dry for 1-2 days

27. Rinse mould and deckle after every use, wash off any fibers by hand

28. Repeat steps 2-26 for all trials and vegetables

29. After drying, make observations (smoothness and colour)

30. Hold the handmade paper up to a light source, such as a flashlight

31. Observe and record any variations in opacity, such as the amount of light passing through the paper

32. Note any patterns or irregularities in the paper's transparency

33. Repeat 29-31 steps for normal A4 paper

34. Use the micrometer or caliper to measure the thickness of the paper

35. Repeat the measurement at different points on the paper for consistency

36. Record the measurements

37. Repeat 33-35 steps for normal A4 paper

38. Place one of the flat surfaces on a stable table

39. Put the handmade paper on top of the surface

40. Add weights gradually to the centre of the paper until it fails (tears or breaks)

41. Record the weights added at the point of failure

42. Repeat 37-40 steps for normal A4 paper

43. Grab new sheet of paper with the same vegetable pulp

44. Fold the dried, handmade paper into smaller sections for testing

45. Use the Sharpie marker to write on one section and the Crayola marker on another

46. Observe for bleeding and spreading of ink on the paper

47. Note any differences in the performance of the two markers

48. Repeat 43-47 steps for normal A4 paper

49. Use the dropper to drop water onto one section of the paper

50. Observe how the paper reacts to the water (absorption, beading, etc.)

51. Measure the amount of water absorbed using the measuring flask

52. Repeat 49-51 steps for normal A4 paper

53. Repeat steps 29-52 for other two trials

54. Repeat steps steps 29-53 for all vegetables

55. Record all results and organize all data into graphs

Observations

During our papermaking process, there were a few initial observations to note. The harder vegetables, specifically the root vegetables, were much harder to blend into a finer, homogenous pulp. We also noticed that it was quite hard to get a perfectly flat and spread-out sheet as the pulp was difficult to disperse throughout the water evenly. After making the sheet, we noticed some minor splits and cracks where the water was draining from the paper. Then, during the drying process, we saw that some of the papers began to form small cracks and tears, primarily on the edge. The felt had also started to curl up at the edges, causing the paper to become slightly warped, as well as some of the papers drying slightly inconsistently, with some patches becoming drier faster than others. Most of them did not have any scent or a very minimal earthy smell, however, the potato had a very strong and distinct odor as it was drying. Additionally, the carrot and potato samples took the longest to dry, taking almost 3 days. We noticed that although fully dehydrated, the potato and carrot samples still had a slightly soft, spongy texture. The papers lost their tint and transformed into a cream shade. After drying, the root vegetables formed a coarse texture. skin and other stems of the vegetables were apparent in the paper. Some vegetables, especially carrots and cauliflower, developed the textures of fabric. Many papers were thicker and more durable. We saw that that peas and cabbage had the whitest-looking paper with splotches of green, they also seemed the most resistant to bends and twists as they were much sturdier. The potato turned brownish, and the carrot stayed bright orange. The papers also happened to pick up the texture of the felt, leaving an imprint on the back.

Across various trials, significant variability in thickness is observed, with radish paper consistently appearing the thickest, followed by potato, peas, cauliflower, cabbage, and carrot papers. Peas demonstrate the highest weight-holding capacity, suggesting suitability for applications requiring strong structural support, while cauliflower paper consistently exhibits superior marker performance with minimal bleed through. Additionally, peas display the highest water-holding capacity, indicating potential for tasks requiring high water absorbency. However, inconsistencies and outliers are noted across trials, emphasizing the need to address factors contributing to variability for reliable performance. Despite this, each vegetable sample offers distinct qualities that could be advantageous in specific applications, such as strength in peas, weight support in cabbage, and reliable ink absorption in cauliflower.

Tables

Graphs

Analysis

To gain insight into the wide range of uses for plant-based materials, we carried out a thorough thickness, marker bleeding, weight, and water holding capacity testing experiments on different samples. Comparing these materials' potential to a control sample that was the average printer paper, or A4 paper. We investigated the water-holding capacity, thickness, weight, marker performance, of the pulp of certain vegetables. We took and utilized the vegetable scraps, using its pulp and cellulose to create paper. These vegetables included, carrots, potatoes, cabbage, peas, radish, and cauliflower. In an effort to identify special qualities and possible uses for each vegetable-derived material.

In our thickness testing, we sought comprehensive insights by examining all samples to provide a well-rounded comparison against the control sample, which measures 0.1 mm in thickness. Peas and potatoes tended to be thicker than the control sample, with peas having the thickest measurements in some trials. Radish, cauliflower, and cabbage showed varying thickness across trials, indicating some level of inconsistency, while carrot had pretty close measurements compared to the control sample. The thickness of peas varied throughout the trials, ranging from 0.6 mm to 1.7 mm. With an average of 0.97, our measurement of 1.7mm from the peas sample was a significant outlier. Radish exhibited a moderate range of thickness, ranging from 0.4 mm to 1.7 mm. The measurements were diverse across trials, with some trials showing thickness close to the control sample and others having notably thicker values. Following radish, the potato samples were the third thickest paper, with an average thickness of 1.07mm, and a range from 0.7 mm to 1.7 mm. This vegetable had some trials with thickness surpassing the control sample, indicating its potential for providing a thicker material that may necessarily work for a4 paper, which is what this project is considering, however it has potential for alternative papers such as watercolor. Cauliflower had thickness ranging from 0.6 mm to 1.1 mm. Its average was 0.84, which performed mediocre compared to the other tests.The cabbage had quite a large range, from 0.4 mm to 1.5 mm, with its average being 0.74. However, most of the papers were quite even, most of them being 0.5 mm, despite the significant outlier of the 1.5mm sample. Last but not least, the carrots. Carrot had thickness values ranging from 0.3 mm to 0.8 mm, which was the most similar to the control. However, despite this, the carrot sample did have quite a few holes and tears in it, so while being the thinnest, it also ended up one of the weakest.

During our weight testing, peas consistently showed the highest weight-holding capacity across all trials, with Trial 1 being notable at having the highest value, which was 4000g. Its average was also one of the highest, being 1693.33g. Radish displayed a modest weight-holding capacity in the first trial, recording 590g, suggesting moderate capabilities in retaining weight. With its second and third trial it doubled its capacity performing much better overall. Radish and cauliflower exhibited varying water-holding capacities across trials.Cauliflower exhibited a substantial weight-holding capacity in the first trial, reaching 1700g. However, there was a significant decrease in weight retention in the second trial, showcasing variability in its weight-holding capabilities. Potatoes consistently showed a moderate to high weight-holding capacity across all trials, reaching 590g, 980g, and 1090g in Trials 1, 2, and 3, respectively. The lumpy texture of potatoes, coupled with their inherent moisture content, likely contributed to their notable weight retention abilities. Carrots exhibited a relatively low weight-holding capacity in the first trial, recording 190g, indicating limited abilities in retaining weight. The subsequent increase to 490g in the second trial and decrease to 240g in the third trial suggest variability in carrot's weight retention, possibly influenced by factors like fiber content or cellular structure. Cabbage displayed significant variability in weight retention across trials, with Trial 1 reaching 3200g, Trial 2 dropping to 2090g, and Trial 3 increasing again to 3800g. This variability could be attributed to factors such as cabbage density, structure. Cabbage shows variability, which may be influenced by factors such as size or condition. It demonstrated a fluctuating water-holding capacity, with Trial 1 and Trial 3 having higher values compared to Trial 2. The control sample, while providing consistent results, had a lower weight-holding capacity compared to peas in Trial 1.

For our marker tests we decided to draw a single 5 cm line in 5 seconds, and trace the same line back with the same restrictions to ensure measurable and reliable data for our results. Peas, radish, potato, cabbage and carrot all bleed through in one trial, showing some indications of inconsistencies in the fiber composition and thickness. Peas exhibited bleed through in the first trial but improved in subsequent trials, showing a reduced tendency to bleed. Radish displayed variability in bleeding characteristics, with instances of bleed through in both the first and third trials. For the cauliflower we noticed, cauliflower consistently did not bleed in all trials, indicating good performance in terms of ink absorption, being the most consistent for papermaking. Potato showed a tendency to bleed through in the third trial, suggesting a potential issue with ink absorption. Carrot exhibited bleed through in the first trial but improved in subsequent trials, showing better resistance to bleeding. Cabbage demonstrated variability, with bleed through in the second trial but good performance in the other trials. For the cauliflower we noticed, it consistently did not bleed in all trials, indicating good performance in terms of ink absorption, being the most dependable and most comparable to the control. Cauliflower consistently did not bleed in all trials, indicating reliable ink absorption capabilities. Peas and radish showed improvement in bleeding characteristics across trials, with peas initially bleeding but reducing in subsequent trials. Potato, carrot, and cabbage exhibited variability in bleeding characteristics. The potato showed bleeding in the third trial, while carrot improved after an initial bleed in the first trial. Cabbage showed bleed through in the second trial. Understanding the bleeding characteristics of these vegetables is important for applications where ink absorption and bleed resistance are critical factors. It's noteworthy that the performance of each vegetable may be influenced by factors such as fiber composition, density, and inherent moisture content.

The water tests showed that all vegetables held water between 0.25-1.5g, with peas outperforming the control sample. We noticed that all the results were within a similar range, meaning all of them performed pretty similarly in comparison to the control sample (A4). All of the averages from the samples tested from the vegetables actually outperformed the control sample, the highest average being from peas which scored an average of 1.25g of water held, almost 3 times the amount of water the control held. This could possibly be due to the fact that the peas were quite thicker than the others, in particular, the eighth trial of peas was 1.7 mm, which was significantly thicker than the control, which was only around 0.1mm. This could be a problem however, as thicker paper makes it more difficult to manipulate and write on. Following the peas, the cabbage performed second best, all of the trials holding 1g of water. Cabbage was quite consistent showing us the same result throughout our testing. Cabbage was able to hold quite a lot of water due to resistant qualities, this can also be attributed to its ability in contain larger amounts of water in comparison. Potato was extremely similar to cabbage, though it had a much higher thickness its lumpy texture was able to absorb a notable quantity of water. The third-best performer was the radish, which had an average water holding capacity of 0.625g. While it didn't match the levels of peas and cabbage, it still outperformed the control sample, indicating decent water absorbency. Radish demonstrated consistency within its trials, staying within the range of 0.5g to 0.75g. Cauliflower and carrot, while still showing water-holding abilities, performed slightly lower than the other vegetables. Cauliflower had an average of 0.875g, with a range from 0.5g to 1g, while carrot had an average of 0.75g, with a range of 0.5g to 1g. These two vegetables might be suitable for tasks that don't require a high water absorption capacity.

The data provided offers insights into the characteristics of paper made from various vegetables compared to traditional A4 paper. Thickness measurements reveal variability across different vegetable papers, with radish paper showing the highest average thickness of 1.21mm, followed by potato, peas, cauliflower, cabbage, and carrot papers. In terms of weight, cauliflower paper exhibits the highest average weight, followed by carrot, radish, and peas papers, while A4 paper falls within the observed range of weights. Water absorption varies among vegetable papers, with peas paper displaying the highest average absorption, followed by cauliflower, radish, carrot, cabbage, and potato papers, with A4 paper showing relatively lower absorption. For the marker testing, all papers performed much better than the control sample, which may hint that these papers could possibly be an alternative to creative and cardstock specialty papers. Overall, the data highlights differences in thickness, marker, weight, and water absorption among vegetable papers, suggesting unique properties and performance compared to traditional A4 paper.

Although most of our data followed a limited range, we did have some outliers. Trial 2 for peas in the water test, with a weight of 1.5g, is considered an outlier because it deviates significantly from the trend observed in other water tests for peas. The higher water-holding capacity in Trial 2 stands out compared to the other trials, making it an outlier. Trial 3 for peas in the weight test, with a weight of 0.5g, is considered an outlier because it substantially differs from the average weight observed in other trials. This deviation could be attributed to variations in the pea sample or potential errors in the weight measurement during trial 3. Trial 8 for peas in the thickness test, with a thickness value deviating from the general trend, is considered an outlier. This discrepancy may be attributed to measurement errors, variations in the pea samples, or other external factors influencing the thickness measurement in trial 8. While peas was a vegetable that performed fairly well, it was unfortunately an inconsistent vegetable with multiple outliers. Some of our other outliers include, trial 3 for radish in the thickness test, which is considered an outlier due to its thickness value significantly deviating from the typical trend observed in other trials. Factors such as irregularities in the radish sample or measurement errors may contribute to this outlier. Trial 1 for cauliflower in the weight test is considered an outlier due to its weight value deviating significantly from the average weight observed in other trials. Possible factors contributing to this outlier include irregularities in the cauliflower sample or errors in the weight measurement during trial 1. This wraps up our outliers. While they are important to observe and analyse, we believe that in a factory setting, all of these would become completely the same, which is why in our project we believe they are an easier fix.

A range of findings have been gathered through our investigation into the water-holding capacity, thickness, weight, and marker performance of materials derived from vegetables. Every vegetable sample has distinct qualities that could be useful in a variety of situations. Peas are strong, but cabbage is the best at supporting its own weight. The most dependable for marker applications is cauliflower, which shows the least amount of ink bleed. These results highlight the delicate balance between thickness, strength, and functionality in vegetable-based materials and provide opportunities for additional study and thought. These analyses provide a starting point for further exploration of the possibilities, opening the door to creative applications of natural materials across a range of industries.

Conclusion

In conclusion, our hypothesis was incorrect, as the paper created by the cabbage pulp performed the overall strongest in comparison to the other vegetables. Not only was it the strongest in the testing, but it produced a paper most similar to the a4 in terms of texture, appearance, weight and overall performance.. Even though it did not perform Despite it not performing the strongest overall, it still was very impressive, and considering all factors, it was the best., It also was the also being the most appealing looking paper, as it was an appropriate thickness and remained much flatter than the other tests. This is probably most important to consumers, as they would want a paper that's not only sturdy, but flexible for arts and crafts uses, as well as aesthetically pleasing to look at. The peas and radish also performed sufficiently, however in terms of aesthetics, they appeared less similar to the control than the cabbage. The potato, cauliflower, and carrot, performed more poorly overall, and lacked especially in aesthetics. They were quite hard to form into a uniform sheet, and once dried, some bits separated, causing cracks and rips through the entire paper. This means they probably would not be suitable or functional, as they would be too brittle to manipulate or write on.

Application

This project directly correlates with real world problems because it helps battle environmental issues as well as sustainability ones. Excessive logging directly affects the environment in multiple negative ways, including increased greenhouse gas emissions, increased soil erosion, and disruption of habitats. If certain vegetable scraps prove to be suitable for papermaking, it could contribute to sustainable and eco-friendly paper production, decreasing the amount of trees that need not be cut down for paper production. Michelle Dias, an expert working at the head office of the waste facilities at the City of Calgary, had a positive approach when asked about this project. She states,” I believe this idea is sustainable design, taking innovative practices and combining it with reduce and recycle approaches.” We believe that this science fair idea goes hand in hand with reducing our ecological impact and sustainability practices. This papermaking project holds significant real-world relevance by addressing two key issues: sustainable resource utilization and waste reduction. By repurposing food scraps, specifically root vegetables, into paper, the project contributes to minimizing food waste and promoting a more circular economy. Food waste is a global concern with environmental, economic, and social implications, and innovative initiatives like this one demonstrate a practical approach to transforming organic waste into valuable products. Additionally, the project aligns with sustainable practices by offering an alternative to conventional paper production methods, potentially reducing the reliance on virgin wood pulp and minimizing the environmental impact associated with traditional papermaking. With the growth and expansion of these papers, we would have a reusability step in between the compost practices, as when contacting the City of Calgary waste facilities office, they claimed that our papers could be completely compostable. Converting to these alternatives will decrease the ecological importance of forests that would be cut down. Using this method, we could again recycle this paper or even compost it, as it is fully biodegradable, this leads to no excess of problems created by our project. Overall, our science fair project showcases the potential for creative solutions in sustainable materials development and waste management and recued ecological impact on the earth.

If we were to do this experiment again, we would like to extend our project even further, probably including more trials, as well as test more different vegetables to explore the use of other vegetable scraps or even combine them, just likeas hardwood and softwood are typically combined to make a perfect blend of pulp most suitable for papermaking. We would also hopefully be able to refine our paper in proper industry tools and practices, as well investing in better equipment to achieve better and more consistent results. Experimenting with different mesh sizes or altering the pulp-to-water ratio could help identify optimal conditions for preventing cracks and improving overall sheet quality. Further investigation into the drying process may involve analyzing the drying environment, such as temperature and humidity fluctuations. To address the issue of small cracks forming primarily on the edges of the paper during drying, adjusting the drying conditions or experimenting with different drying surfaces could be explored. Additionally, variations in the thickness of the paper and the impact on drying time and consistency could be considered to refine the drying process. Regarding the observed curling of the felt at the edges during drying, exploring alternative drying surfaces or adjusting the tension during the drying process might mitigate this issue.

Contacting and working together with more experts in the papermaking field would also be extremely helpful for this idea, and it would help us hopefully create a more successful model of this product. We did contact multiple additional experts from various fields, some of these included food scientists, paper manufacturers, forest resources, environmentalists, compost and recycling management, grocery stores and university professors, however, some of them were not able to give a response in time for our project. Last but not least, exploring additional parameters, such as paper texture and durability, would be beneficial to more comprehensively evaluate the quality of the paper.

Sources Of Error

The experiment's outcome could have been affected by several sources, including faulty measurement equipment or inaccurate kitchen scales. Also, due to our mould and deckle method, it was difficult to ensure that every sheet was the same thickness and opacity throughout all of the tests, which can affect its overall performance. Additionally, textural inconsistencies were observed, with some parts having more pulp/skin buildup than others. Discoloration was also observed in the samples. Also, since we were working on a limited budget, we had only had access to a traditional food processor, which is evidently much weaker then the industrial mixers as you can tell on the pictures and our samples we have here for you. This meant we weren't able to get a completely homogeneous pulp on all of the vegetables, in particular the root vegetables, as they had a harder texture. Additionally, exploring alternative methods to enhance the blending process, such as pre-soaking or adjusting blending times, could be considered to address the difficulty in achieving a homogenous pulp. We also noticed some discoloration throughout the samples. Since we were working on a limited budget, we had only had access to a traditional food processor, which is evidently much weaker then the industrial mixers as you can tell on the pictures and our samples we have here for you. Additionally, the paper size prevented pressuring down the samples, causing them to curl upwards and bend slightly. While this shouldn't affect the paper composition, it could have caused inconsistencies in thickness and overall strength.

Citations

Website Citations

- Hampberg, Ava Saffrium. “Is Paper Better than Plastic?” Edited by Ouelyia Nifemi, BBC News, BBC, 29 Oct. 2022, www.bbc.com/future/bespoke/made-on-earth/how-paper-is-making-a-comeback/.

- Chatterjee, Siddharth. “Tree Wood Classification and Composition: Importance of Cellulose, Hemi-Cellulose and Lignin.” Pulp & Paper, ABB Group, 8 Mar. 2013, new.abb.com/pulp-paper/abb-in-pulp-and-paper/articles/characteristics-of-wood-and-papermaking-fibers.

- Sahin, Halil Turgut, and Mustafa Burak Arslan. “A Study on Physical and Chemical Properties of Cellulose Paper Immersed in Various Solvent Mixtures.” International Journal of Molecular Sciences, U.S. National Library of Medicine, 1 Feb. 2008, http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2635603/.www.ncbi.nlm.nih.gov/pmc/articles/PMC2635603/.

- Xiao, Sai Yousef. “Fibre Sources.” Encyclopædia Britannica, Encyclopædia Britannica, inc., 27 Apr. 2020, www.britannica.com/technology/papermaking/Fibre-sources.

- Galioeno, James, and Mahyaka Ellia Huakoa. “Hemicellulose.” Hemicellulose - an Overview | ScienceDirect Topics, 16 Feb. 2018, www.sciencedirect.com/topics/materials-science/hemicellulose.

- Baker, N. (2016, July 1). Basics of Paper Manufacturing - Oklahoma State University. Basics of Paper Manufacturing | Oklahoma State University. https://extension.okstate.edu/fact-sheets/basics-of-paper-manufacturing.html#:~:text=Typical%20mechanized%20paper%20production%20involves,sheet%20in%20a%20Fourdrinier%20machin

- Vougn, Janetly. “From the Woods: Paper!” Penn State Extension, Penn State Univeristy, 2018, extension.psu.edu/from-the-woods-paper

- Aubrey, Allison. “From McDonald’s to Organic Valley, You’re Probably Eating Wood Pulp.” NPR, 10 July 2014, www.npr.org/sections/thesalt/2014/07/10/329767647/from-mcdonalds-to-organic-valley-youre-probably-eating-wood-pulp#:~:text=Cellulose%20is%20basically%20plant%20fiber,turning%20up%20in%20our%20food.

- Author links open overlay panelDavid Paton 1, Kara, et al. “Cellulose from Apple Tissue: Isolation, Purification and Chemical Modification.” Canadian Institute of Food Science and Technology Journal, Elsevier, 18 Apr. 2013, www.sciencedirect.com/science/article/abs/pii/S0315546374738494.

- Author links open overlay panelDereca Watkins, Kalani Pham, and Diana Fanzhu AbstractLignocellulosic biomass has been acknowledged for potential use to produce chemicals and biomaterials. Lignin is the second most abundant natural polymer with cellulose being number one. “Extraction and Characterization of Lignin from Different Biomass Resources.” Journal of Materials Research and Technology, Elsevier, 28 Nov. 2014, www.sciencedirect.com/science/article/pii/S2238785414000982#:~:text=Extraction%20of%20lignin%20from%20different,consequently%20retrieving%20by%20washing%20them.

- Author links open overlay panelIzharul Haq a, N, et al. “Recent Advances in Removal of Lignin from Paper Industry Wastewater and Its Industrial Applications – A Review.” Bioresource Technology, Elsevier, 5 June 2020, www.sciencedirect.com/science/article/abs/pii/S0960852420309081.

- Author links open overlay panelS. Lacorte, Kie Yun, et al. “Organic Compounds in Paper-Mill Process Waters and Effluents.” TrAC Trends in Analytical Chemistry, Elsevier, 2 Dec. 2003, www.sciencedirect.com/science/article/abs/pii/S0165993603010094.

- Author links open overlay panelZhijun Shi a b, et al. “Utilization of Bacterial Cellulose in Food.” Food Hydrocolloids, Elsevier, 25 July 2013, www.sciencedirect.com/science/article/abs/pii/S0268005X13002142.

- Black, Coolins, and Georgie Hart. “Pulp and Paper Production from Oil Palm Empty Fruit Bunches: A ... - MYJAFE.” MYJAFE, Jafe, 31 Apr. 2023, myjafe.com/wp-content/uploads/2020/07/MYJAFE2020-0017.pdf.

- Chen, Aaron. “Preparation of Leafy Vegetable Paper - Zheng - 2010 - Wiley Online Library.” Wiley Library , 18 Oct. 2023, http://ifst.onlinelibrary.wiley.com/doi/10.1111/j.1745-4549.2009.00367.x.ifst.onlinelibrary.wiley.com/doi/10.1111/j.1745-4549.2009.00367.x.

- City of Calgary, director. Calgary Recycling: How Recyclables Are Sorted. Youtube, 2013, www.youtube.com/watch?v=Zhv-Dv9h3J4&t=3s.

- City Of Calgary, director. How Compost Is Made: Calgary’s Green Cart Program. YouTube, YouTube, 20 Mar. 2019, www.youtube.com/watch?v=NGopFxRsQWg&t=1s.

- Dr. Binocs Show, director. Invention Of PAPER | The Dr. Binocs Show | Best Learning Video for Kids | Fun Preschool Learning. Dr. Binocs Show, 2017, www.youtube.com/watch?v=COxB_GvdzWI.

- Gadgets, Cheddar, director. How Wood Turns Into Paper. Cheddar Gadgets, 2019, www.youtube.com/watch?v=GuMsRWqPc2k.

- Gorrdenshetn, Ava. “Effect of Protein–Starch Interactions on ... - Wiley Online Library.” Wiley Library , 2013, ift.onlinelibrary.wiley.com/doi/abs/10.1111/1541-4337.13141.

- Grant, Gander G. “Our Sustainable Kraft Pulp Production Proccess: Paper Excellence.” Paper Excellence Group, 17 Jan. 2024, paperexcellence.com/pulp/how-we-make-pulp/.

- Holwegner, Andrea. “Top 7 Healthy Vegetables on a Budget.” Health Stand Nutrition - Online Nutritionist Calgary Dietitian Team, City of Calgary, 17 Nov. 2022, www.healthstandnutrition.com/healthy-vegetables-on-a-budget/.

- Jaques, Colliques. “How to Make Your Own Paper | Artsy.” Artsy, 2019, www.artsy.net/article/artsy-editorial-crash-course-basic-papermaking.

- Kaur, Sabeen. “Paper & Board.” Starch Europe, 19 Oct. 2020, starch.eu/ingredient/paper-board/#:~:text=Typically%20printing%20and%20writing%20papers,quality%20of%20fibres%20during%20recycling.

- NevermindPaper, director. How to Make Recycled Paper (+ Mould & Deckle Diy) | Tutorial. YouTube, YouTube, 2 Apr. 2021, www.youtube.com/watch?v=5xrWrKIVBgo.

- Obeluovi, Mastaru. “Properties of Wood.” Properties of Wood (for Papermaking), Paper Co., 1 Jan. 2024, www.paperonweb.com/wood.htm.

- Paradis, Gaia. “Edible Paper.” PEER2PICKLE, 2 Sept. 2017, peer2pickle.weebly.com/edible-paper.html.

- Rachael, Simone. “Top 9 Cheapest and Healthiest Green Veggies.” DFD Russell Medical Centers, 16 Feb. 2023, dfdrussell.org/cheapest-and-healthiest-veggies/

- Samani, Niti. “Paper Manufacturing: Critical Issues and Challenges.” Deskera Blog, 15 Mar. 2023, www.deskera.com/blog/paper-manufacturing-critical-issues-and-challenges/#:~:text=The%20production%20of%20wood%20pulp,biodiversity%2C%20and%20other%20environmental%20problems.

- Science, Mystery, director. How Do They Turn Wood into Paper? Mystery Science, 2017, www.youtube.com/watch?v=0VEJCWvfhQg.

- Shazhou, Darren. “Papermaking.” Papermaking - an Overview | ScienceDirect Topics, Oct. 2022, www.sciencedirect.com/topics/agricultural-and-biological-sciences/papermaking#:~:text=Starch%20is%20used%20as%20a,maize%2C%20wheat%2C%20and%20tapioca.

- State , Penn. “From the Woods: Paper!” Penn State Extension, Penn State, Mar. 2015, extension.psu.edu/from-the-woods-paper.

- Teagan, Reign. “Read ‘Diet and Health: Implications for Reducing Chronic Disease Risk’ at Nap.Edu.” 10 Dietary Fiber | Diet and Health: Implications for Reducing Chronic Disease Risk | The National Academies Press, 2019, nap.nationalacademies.org/read/1222/chapter/13#293

- Team, BioPak. “Compostable vs Recyclable: Which Is Better for the Environment?” Compostable vs Recyclable | BioPak Australia, BioPak, 17 Jan. 2024, www.biopak.com/au/resources/recycling-vs-composting#:~:text=Composting%20is%20for%20organic%20matter,to%20produce%20nutrient%2Drich%20compost

- Team, Deskera Content. “Ensuring Quality Control in Paper Production.” Deskera Blog, 25 Mar. 2023, www.deskera.com/blog/quality-control-in-paper-production/#:~:text=Tensile%20strength%2C%20tear%20strength%2C%20and,a%20given%20amount%20of%20time

- Thestu, Matteo. “Why Is Printing Important for Business?” Cherrill Print, 8 Apr. 2021, cherrillprint.co.uk/why-is-printing-important-for-business/#:~:text=Printing%20can%20easily%20adapt%20to,that%20you%20might%20be%20based

- Tube, Sappi, director. The Paper Making Process. YouTube, YouTube, 2 Mar. 2012, www.youtube.com/watch?v=E4C3X26dxbM

- Xaila, Grande. “Properties of Wood.” Properties of Wood (for Papermaking), Paper Co., www.paperonweb.com/wood.htm.

- Yousef, Anizla. “Pulp and Paper.” WWF, World Wildlife Fund, www.worldwildlife.org/industries/pulp-and-paper#:~:text=Deforestation%20and%20Forest%20Degradation&text=Irresponsible%20harvesting%20from%20natural%20forests,species%20and%20cause%20soil%20erosion

- Saini, Sajan. “What Makes Wood Rot so Slowly? Cellulose, a Densely Packed Component of Wood, Slows down This Inevitable Decay….” MIT School of Engineering, MIT, 29 Mar. 2011, engineering.mit.edu/engage/ask-an-engineer/what-makes-wood-rot-so-slowly/. Accessed 13 Feb. 2024.

Picture Citations

- Graymont.com, 2024, www.graymont.com/sites/default/files/inline-images/papier-1134070945.jpg. Accessed 14 Mar. 2024.

- Slate.com, 2024, compote.slate.com/images/f4181d74-3ad7-4ef5-ba66-76f115ea2205.jpeg?crop=1560%2C1040%2Cx0%2Cy0. Accessed 15 Mar. 2024.

- Bendigoadvertiser.com.au, 2024, www.bendigoadvertiser.com.au/images/transform/v1/crop/frm/silverstone-feed-data/201c28c1-4f41-42c1-bd19-00545d7bb40f.jpg/r0_0_800_600_w800_h600_fmax.jpg. Accessed 15 Mar. 2024.

Psu.edu, 2024, www.e-education.psu.edu/egee439/sites/www.e- - education.psu.edu.egee439/files/Lesson05/Images/Lesson5_MaltoseHaworth.png. Accessed 15 Mar. 2024.

- Figure 1. Chemical Structure of Lignin., www.researchgate.net/figure/Chemical-structure-of-lignin_fig1_323923688

- http://education.psu.edu.egee439/files/Lesson05/Images/Lesson5_MaltoseHaworth.png. Accessed 15 Mar. 2024.

- Banner: “Food Banner Stock Images.” Dreamstime, www.dreamstime.com/illustration/food-banner.html. Accessed 15 Mar. 2024.

- Pulp Paper Manufacturing Process. Pulp and Paper Technology. https://industry.pulpandpaper-technology.com/articles/1503062873-pulp-paper-manufacturing-process.jpg Accessed 15 Mar. 2024.

- Wood-Paper Manufacturing Flat Infographic Schema. Free Pik Infographics. https://img.freepik.com/free-vector/wood-paper-manufacturing-flat-infographic-schema-from-cut-logs-lumber-chips-pulp-converted-paperboard_1284-27047.jpg?w=740&t=st=1710485036~exp=1710485636~hmac=525dea949c9b7eb8463777f27ef32fe314b2f96d3e71072edfbbb43ef2795bca. Accessed 15 Mar. 2024.

- Paper Making Process. Paper Slurry. Square Space. https://images.squarespace-cdn.com/content/v1/64550d259ac5dd782bd3f25f/8f0c8c64-0d74-49fe-95e8-0152239f22dd/papermakingprocess_web.jpg?format=1500w. Accessed 15 Mar. 2024.

- Science Direct. https://ars.els-cdn.com/content/image/1-s2.0-S2468584419300479-fx1.jpg. Accessed 15 Mar. 2024.

- Science Direct. https://ars.els-cdn.com/content/image/1-s2.0-S2589014X22003073-ga1.jpg. Accessed 15 Mar. 2024.

Other

Pictures and Banners Edited on: Google Drawings

Tables Made on: Word Documents

Graphs and Slideshows Made on: Canva

Canva Slideshow Template: https://www.canva.com/p/templates/EAFcBEgfQUs-beige-green-simple-minimalist-social-media-marketing-project-presentation/

Canva Graphs Template: https://www.canva.com/templates/EAFWCAaGhhw-white-green-modern-bar-chart-graph/

Acknowledgement

We would like to give great thanks to everyone who provided support to this project, including all of our experts, our parents, the City of Calgary, Mrs.Fourie, Mrs.Davis, and Mr.Hotzel. We would also like to thank Louis Riel School and CYSF for organizing and providing this opportunity for us, as well as all of our judges who have taken valuable time out of their own days to graciously judge our project.

For all of our experts, we would like to express our heartfelt gratitude to Michelle Dias at the City of Calgary Compost Facility for her invaluable support and assistance in our papermaking process. Special thanks to Shiyi Ou from Jinan University, Guangzhou, China, Department of Food Science and Engineering, for sharing expertise and insights. Our sincere appreciation goes to S. Lacorte at the Department of Environmental Chemistry, IIQAB-CSIC, Barcelona, Spain, for contributing to the environmental aspects of our project. We extend our thanks to Stanford S. Smith, Professor of Forest Resources at Penn State University, and John Coupland from Penn State University's Department of Food Science and Safety for their guidance and expertise. We are grateful to Guang Yang from the Department of Biomedical Engineering, Huazhong University of Science and Technology, China, and Nirakar Sapkota from the Department of Chemistry, St. Xavier’s College, Kathmandu, Nepal, for their international collaboration and valuable contributions. Lastly, we sincerely send thanks to Organic Paper Plus, Staples, White Paper, Spruce It Up, Saskatoon Farms, No Frills, Superstore, Sobeys, Co-op, and the Rolland Sustana Group for their support and resources, which played a crucial role in the success of our project. Your contributions have been instrumental, with all your help, we were able to properly conduct our project. Thank you all for your assistance in answering all of our questions and providing us with support and all relevant resources. We are truly grateful for your collaboration and assistance.